Wannan labarin zai gabatar da ra'ayoyin ƙira da tsarin sarrafawa na murfin akwatin abincin filastik daki-daki, da tsarin sassa na filastik, kayan aiki don cikakken bincike, m zane na mold fasaha.

Mahimman kalmomi: allura mold;Akwatin abincin rana.Tsarin gyare-gyare

Sashe na ɗaya: Binciken tsari na sassan filastik da zaɓi na farko na injin allura

1.1Raw kayan da aikin bincike akwatin abincin rana filastik

Wannan akwatin abincin abincin filastik samfurin filastik ne na yau da kullun a rayuwar yau da kullun, galibi ana amfani dashi don ɗaukar abinci.Yin la'akari da ƙayyadaddun amfani da shi, cikakken bincike game da ayyukan robobi daban-daban, zaɓin abu don polypropylene (PP).

Polypropylene (PP filastik) wani nau'in nau'i ne mai yawa, babu sarkar gefe, babban crystallization na polymer polymer, yana da kyawawan kaddarorin.Lokacin da ba mai launi ba, farar translucent, waxy;Ya fi zafi fiye da polyethylene.Hakanan nuna gaskiya ya fi polyethylene kyau.Bugu da kari, da yawa na polypropylene ne kananan, musamman nauyi na 0.9 ~ 0.91 grams / cubic santimita, yawan amfanin ƙasa ƙarfi, elasticity, taurin da tensile, compressive ƙarfi ne mafi girma fiye da polyethylene.Its gyare-gyaren zafin jiki ne 160 ~ 220 ℃, za a iya amfani da a game da 100 digiri, kuma yana da kyau lantarki Properties da high mita rufi ba ya shafa da zafi.Yawan shayar da ruwa ya fi ƙasa da polyethylene, amma mai sauƙin narke ɓarkewar jiki, hulɗar dogon lokaci tare da ƙarfe mai zafi yana da sauƙi don lalata, tsufa.Ruwan ruwa yana da kyau, amma haɓakar haɓakar haɓakar haɓaka shine 1.0 ~ 2.5%, raguwar raguwa yana da girma, wanda ke da sauƙin kai ga rami mai raguwa, ƙwanƙwasa, nakasawa da sauran lahani.Gudun sanyi na polypropylene yana da sauri, tsarin zub da ruwa da tsarin sanyaya ya kamata a sanyaya sannu a hankali, kuma kula da sarrafa yanayin zafin jiki.Kaurin bangon sassan filastik yakamata ya zama iri ɗaya don gujewa rashin mannewa da kusurwa mai kaifi don hana damuwa.

1.2Analysis na gyare-gyaren tsari na filastik akwatin abincin rana

1.2.1.Binciken tsarin sassa na filastik

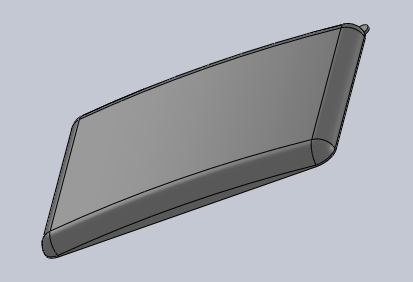

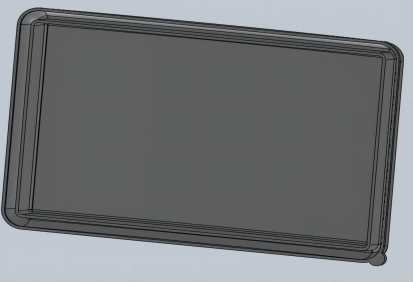

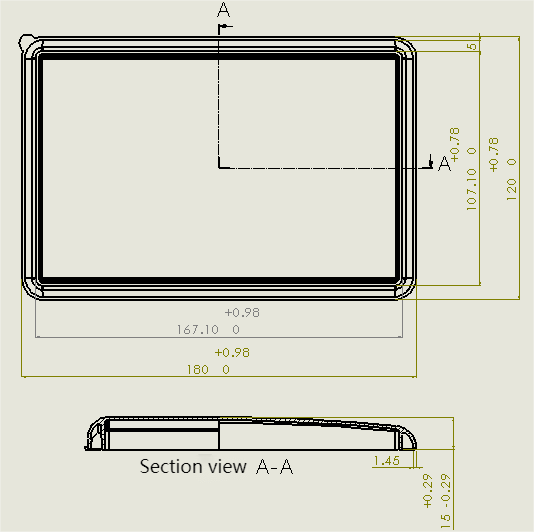

Shawarar kauri na bango na polypropylene ƙananan sassan filastik shine 1.45mm;Matsakaicin girman akwatin abincin rana shine 180mm × 120mm × 15mm;Ɗauki girman bangon ciki na murfin akwatin abincin rana: 107mm;Bambanci tsakanin bangon ciki da na waje shine: 5mm;Kusurwar bangon waje mai zagaye shine 10mm, kuma kusurwar bangon ciki shine 10/3mm.Ɗayan kusurwar murfin akwatin yana da shugaba na annular tare da radius na 4mm.Saboda sassan filastik kwantena ne masu bakin ciki, don hana rashin ƙarfi da ƙarfin da ke haifar da lalacewar sassan filastik, don haka an tsara saman sassan filastik a matsayin da'irar 5mm mai tsayi.

1.2.2.Matsakaicin daidaitaccen bincike na sassan filastik

Girman nau'i biyu na murfin akwatin abincin rana suna da buƙatun daidaito, wato 107mm da 120mm, kuma buƙatun daidaito shine MT3.Tun da yanayin waje na sassan filastik yana da tasiri ta jurewar ma'auni na ɓangaren motsi na mold (kamar gefen tashi), nau'in haƙuri an zaɓi shi azaman darajar B. Idan ba a buƙatar matakin haƙuri ba, an zaɓi MT5. .

1.2.3.Binciken ingancin saman saman sassa na filastik

Daidaitaccen murfin murfin akwatin abincin rana bai yi girma ba, kuma ƙarancin ƙasa Ra shine 0.100 ~ 0.16um.Don haka, ana iya amfani da alluran allura guda ɗaya na mai gudu don tabbatar da daidaiton saman.

1.2.4.Abubuwan kayan abu da girma da ingancin sassan filastik

Nemi kaddarorin kayan filastik na PP (ciki har da modulus na roba, rabon Poisson, yawa, ƙarfin tashin hankali, zafin zafi da takamaiman zafi) a cikin SolidWorks, kuma yi amfani da software na SolidWorks don ƙididdige bayanan sassan filastik (ciki har da nauyi, ƙara, yanki da tsakiya). na nauyi).

1.3 Ƙayyade sigogin tsarin gyare-gyare na sassa na filastik

A cikin aiwatar da gyare-gyaren allura, zafin jiki na Silinda da bututun ƙarfe zai shafi filastik da kwararar filastik, yawan zafin jiki na ƙirar zai haifar da kwararar ruwa da sanyaya na ƙirar filastik, matsa lamba a cikin aiwatar da gyare-gyaren allura zai shafi kai tsaye. plasticization na roba da filastik sassa ingancin.Samar da yanayin tabbatar da ingancin sassa na filastik zai yi ƙoƙarin rage sake zagayowar sassa na filastik, wanda lokacin allura da lokacin sanyaya yana da tasiri mai mahimmanci akan ingancin sassan filastik.

Tambayoyin da za a yi la'akari yayin zayyana:

1) Yin amfani da dacewa da stabilizers, lubricants don tabbatar da aikin aiwatar da filastik PP da kuma amfani da sassan filastik.

2) Ya kamata a hana raguwa, ɓarna, lalacewa da sauran lahani yayin zane.

3) Saboda saurin sanyi mai sauri, kula da yanayin zafi na tsarin zubar da ruwa da tsarin sanyaya, kuma kula da kula da yanayin zafin jiki.Lokacin da zafin jiki ya kasance ƙasa da digiri 50, sassan filastik ba za su kasance masu santsi ba, za a sami waldi mara kyau, barin alamomi da sauran abubuwan mamaki;Fiye da digiri 90 yana da saurin lalacewa da sauran abubuwan mamaki.

4) Kaurin bangon sassa na filastik ya zama iri ɗaya don guje wa damuwa.

1.4 Model da ƙayyadaddun na'ura mai gyare-gyaren allura

Dangane da sigogin tsarin gyare-gyare na sassa na filastik, zaɓi na farko na na'urar ƙirar ƙirar ƙirar G54-S200/400,

Sashi na biyu: Tsarin tsari na akwatin abincin abincin filastik murfin allura

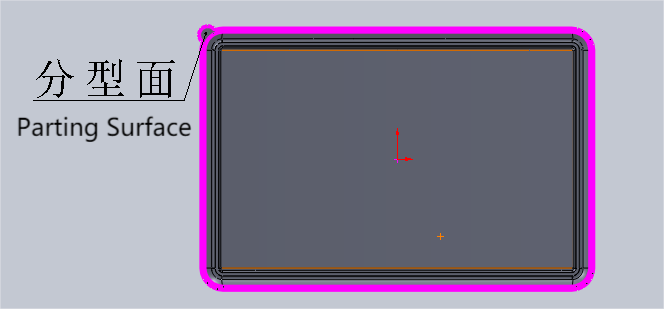

2.1 Ƙaddamar da farfajiyar rabuwa

Ya kamata a yi la'akari da ainihin siffar da yanayin ɓarna na sassa na filastik lokacin zabar farfajiyar rabuwa.Ka'idodin ƙira na farfajiyar rabuwa sune kamar haka:

1. Ya kamata a zaɓi wurin da aka raba a matsakaicin madaidaicin ɓangaren filastik

2. Zaɓin yanki na rabuwa ya kamata ya zama mai dacewa ga ƙaddamar da sassa na filastik

3. Zaɓin zaɓi na rabuwa ya kamata ya tabbatar da daidaiton girman girman da ingancin sassan filastik da buƙatun amfani da su

4. Zaɓin zaɓi na rabuwa ya kamata ya zama mai dacewa ga aiki da sauƙi na mold

5. Rage girman yankin tsinkayar samfurin a cikin hanyar mannewa

6. Dogon tsakiya ya kamata a sanya shi a cikin shugabanci na buɗewar mutu

7. Zaɓin farfajiyar rabuwa ya kamata ya zama mai dacewa don shayewa

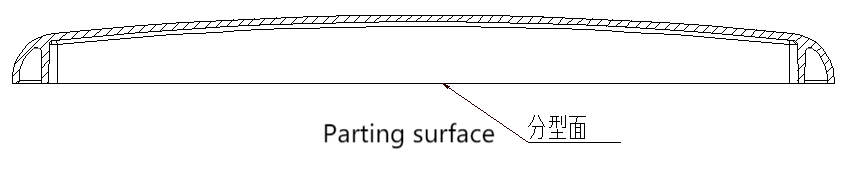

Don taƙaitawa, don tabbatar da ƙaddamar da ƙananan sassa na filastik da kuma buƙatun fasaha na sassa na filastik da sassauƙan masana'anta na ƙirar ƙira, an zaɓi ɓangaren ɓangaren a matsayin ƙananan murfin murfin abincin rana.Kamar yadda aka nuna a hoton da ke ƙasa:

2.2 Ƙididdigar lambar cavity da daidaitawa

Dangane da buƙatun ƙira na littafin ƙirar sassa na filastik, fasalin fasalin tsarin filastik da buƙatun daidaito na girma da buƙatun tattalin arziƙi na samarwa, ƙayyade amfani da ƙira a rami.

2.3 Zane na tsarin zubewa

Wannan ƙirar tana ɗaukar tsarin zubar da ruwa na yau da kullun, kuma ƙa'idodin ƙirar sa sune kamar haka:

Rike tsari gajere.

Ya kamata ya zama mai kyau,

Hana nakasar asali da saka matsuguni,

Hana warping nakasar filastik sassa da samuwar sanyi tabo, sanyi spots da sauran lahani a saman.

2.3.1 Babban tashar tashar

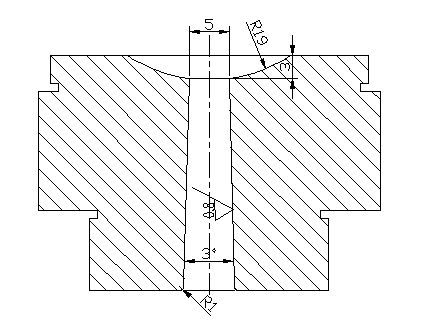

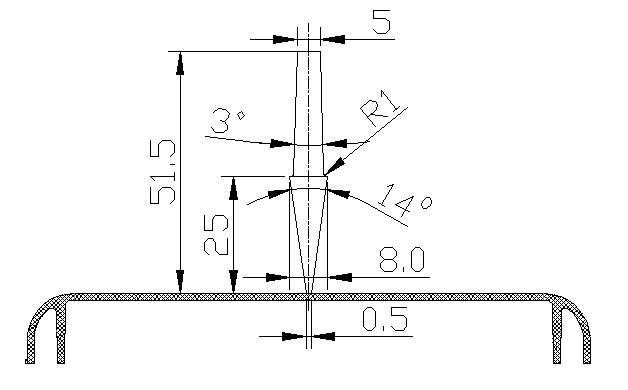

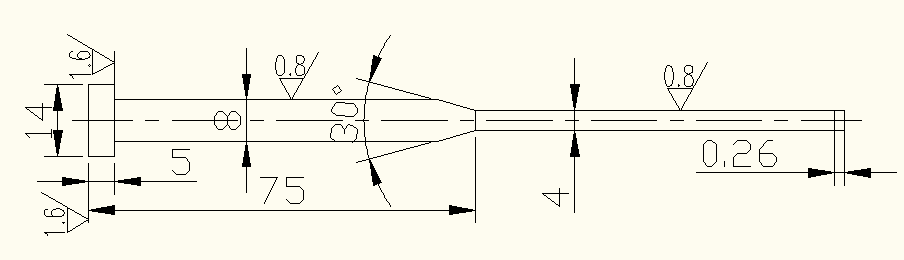

An tsara babban tashar don zama conical, kuma mazugi Angle α shine 2O-6O, da α = 3o.Matsakaicin yanayin tashar tashar Ra≤0.8µm, madaidaicin tashar babban tashar shine canjin fillet, don rage juriya na kwararar kayan zuwa canjin, fillet radius r = 1 ~ 3mm, ana ɗaukar shi azaman 1mm .Babban fasalin tashar shine kamar haka;

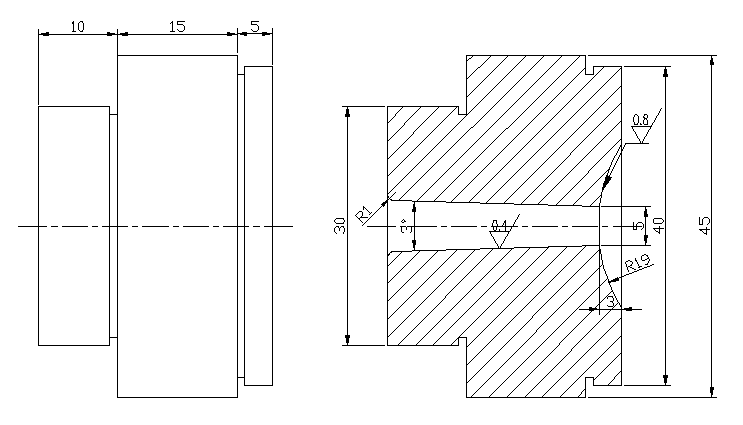

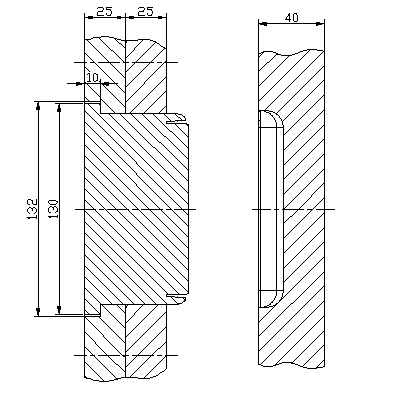

An tsara tsarin hannun rigar ƙofar zuwa sassa biyu ta amfani da hannun ƙofar ƙofar da zobe na matsayi, wanda aka gyara akan madaidaicin wurin zama na mutu a cikin hanyar mataki.

Diamita na ƙaramin ƙarshen hannun ƙofar ƙofar yana da girma 0.5 ~ 1mm fiye da na bututun ƙarfe, wanda aka ɗauka azaman 1mm.Tun da gaban ƙaramin ƙarshen yanki ne, zurfinsa shine 3 ~ 5mm, wanda aka ɗauka azaman 3mm.Tun da sphere na bututun ƙarfe na injunan allura ya haɗu kuma ya dace da ƙirar a wannan matsayi, ana buƙatar diamita na sararin babban tashar ya zama 1 ~ 2mm ya fi girma fiye da na bututun ƙarfe, wanda aka ɗauka azaman 2mm.Ana nuna sigar amfani da sigogin hannun rigar ƙofar a ƙasa:

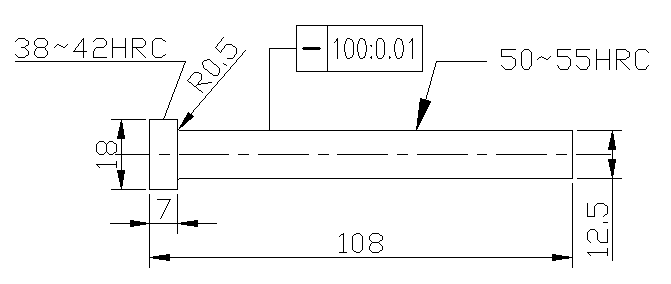

H7/m6 ana ɗaukar dacewa tsakanin hannun hannun ƙofar da samfuri, kuma ana ɗaukar dacewa H9/f9 tsakanin hannun hannun ƙofar da zoben sakawa.Ana shigar da zoben sakawa a cikin rami na kafaffen samfuri na injin allura a lokacin shigarwa da kuma lalata kayan aikin, wanda ake amfani da shi don shigarwa da matsayi na mold da injin allura.A waje diamita na saka zobe ne 0.2mm karami fiye da sakawa rami a kan kafaffen samfuri na allura inji, don haka shi ne 0.2mm.Ana nuna tsayayyen tsari na hannun rigar ƙofar da girman zoben sanyawa a ƙasa:

2.3.2 Tsarin tashar Shunt

Domin zane ne mold wani rami, da parting surface ga kasa na akwatin cover, da kuma ƙofa zabi ga batu ƙofar kai tsaye nau'i, don haka shunt to ba su da zana.

2.3.3 Tsarin kofa

Yin la'akari da buƙatun gyare-gyare na sassa na filastik da gyaran gyare-gyare yana dacewa ko a'a kuma ainihin amfani da halin da ake ciki, don haka an zaɓi zane na wurin ƙofa a matsayin babban cibiyar murfin murfin abincin rana.Diamita na ƙofar batu yawanci 0.5 ~ 1.5mm, kuma ana ɗaukar shi azaman 0.5mm.Angle α yawanci 6o ~ 15o, kuma ana ɗauka azaman 14o.Ana nuna zanen ƙofar a ƙasa:

2.4 Zane na ramin sanyi da jan sanda

Saboda haka, zane shine mold da rami, ƙofar ƙofar kai tsaye zubawa, don haka ramin sanyi da jan sanda ba dole ba ne a tsara su.

2.5 Zane na kafa sassa

2.5.1Ƙaddamar da tsarin mutuwa da naushi

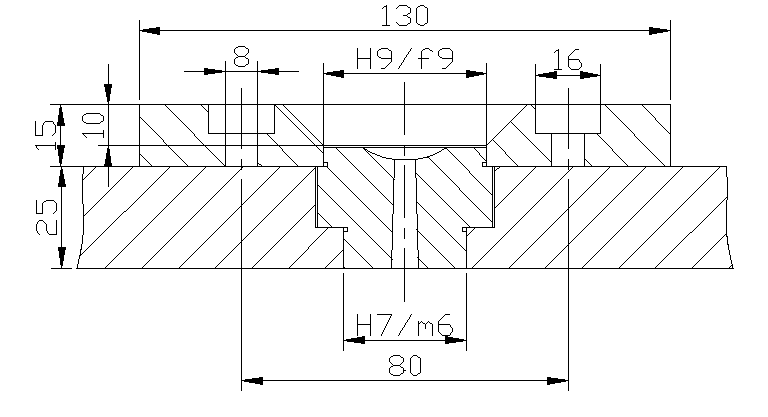

Domin shi ne kananan filastik sassa, wani rami, kuma domin high aiki yadda ya dace, dace disassembly, amma kuma don tabbatar da siffar da girman daidaito na filastik sassa, da zane na overall convex da concave mutu selection ga dukan.The convex die ana sarrafa ta hanyar sarrafa daban, sa'an nan kuma danna cikin samfuri tare da sauyawar H7/m6.Zane-zane na ƙirar tsarin ƙirar convex da concave die shine kamar haka:

2.5.2Zane da lissafi na rami da tsarin tushen

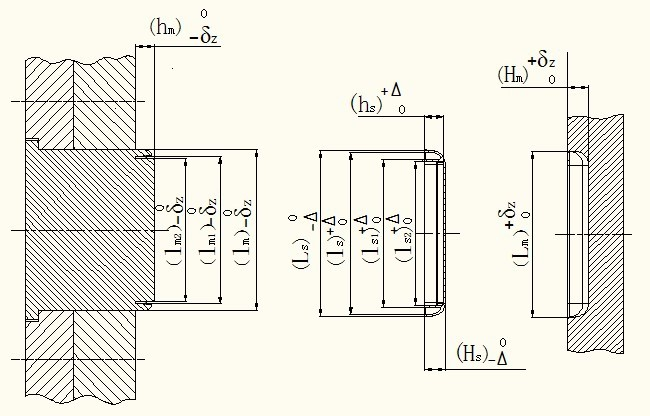

Dangantakar da ke tsakanin girman aiki na ɓangaren mold da girman ɓangaren filastik ana nunawa a ƙasa:

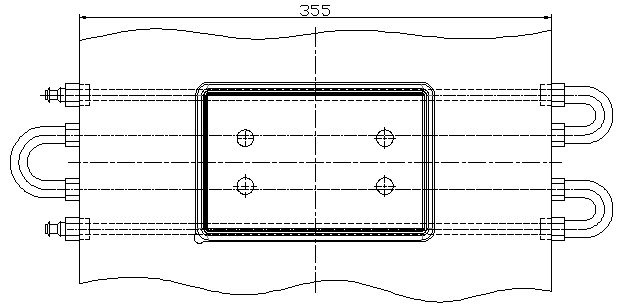

2.6 Zaɓin firam ɗin mold

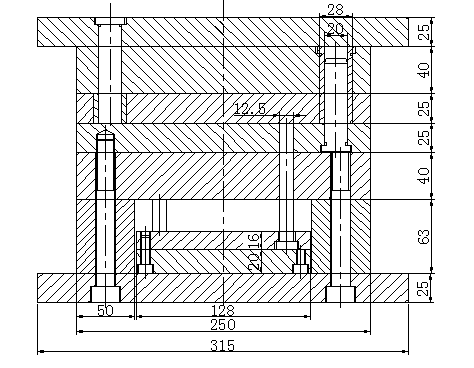

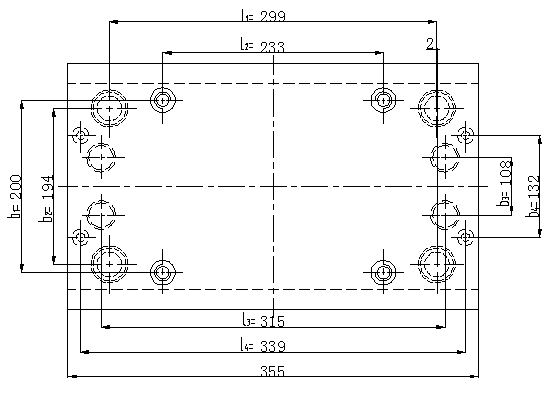

Tun da wannan zane ne ga kananan da matsakaici-sized filastik sassa, da mold frame ne P4-250355-26-Z1 GB / T12556.1-90, da kuma B0 × L na mold frame ne 250mm × 355mm.

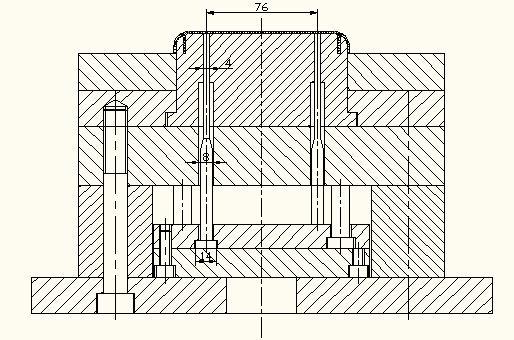

Jadawalin taro na mold shine kamar haka:

2.7 Tsarin sassa na tsari

2.7.1Tsarin tsari na jagora

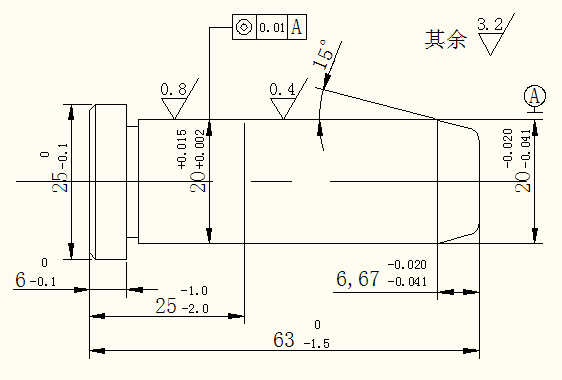

Diamita na sakon jagora shine Φ20, kuma kayan da aka zaɓa don jagorar jagorar shine karfe 20, tare da carburizing na 0.5 ~ 0.8mm da quenching hardness na 56 ~ 60HRC.The chamfered kusurwa da aka nuna a cikin adadi bai wuce 0.5×450 ba.An sanya alamar jagorar a matsayin Φ20 × 63 × 25 (I) - 20 karfe GB4169.4 - 84. H7 / m6 mika mulki ya dace tsakanin ƙayyadaddun ɓangaren ɓangaren jagora da samfurin.Wani jagorar sakon yana da alamar Φ20 × 112 × 32 - 20 karfe GB4169.4 - 84.

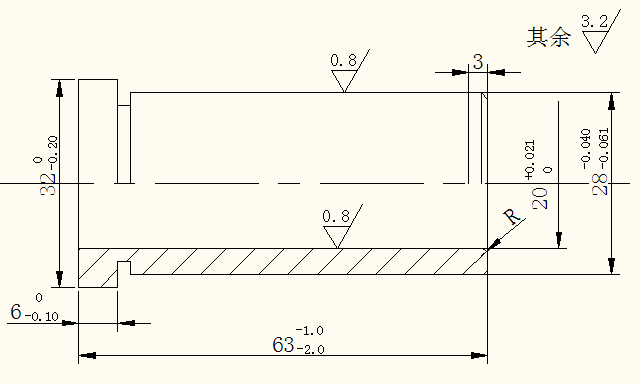

2.7.2Tsarin tsarin hannun rigar jagora

Diamita na hannun rigar jagora shine Φ28, kuma kayan aikin jagorar shine 20 karfe, carburized 0.5 ~ 0.8mm, kuma taurin maganin da aka kashe shine 56 ~ 60HRC.Chamfering da aka nuna a cikin adadi bai wuce 0.5×450 ba.An yi wa hannun rigar jagora alama a matsayin Φ20 × 63 (I) - 20 karfe GB4169.3 - 84, kuma daidaitattun daidaito na gidan jagora da hannun rigar jagora shine H7/f7.Wani hannun rigar jagora mai alama Φ20×50(I) - 20 karfe GB4169.3 - 84.

2.8 Ƙaddamar da ƙirar tsarin

Tsarin turawa gabaɗaya ya ƙunshi turawa, sake saiti da jagora.

Saboda sassan filastik suna da ɗan ƙaramin ƙarfi, a cikin yanayin ƙoƙarin tabbatar da ingancin sassan filastik, ƙirar ƙirar ƙirar ta ɗauki sandar fitarwa don fitar da sassan filastik.

Zane-zane na tsarin ƙaddamarwashine kamar haka:

Tsarin da sigogi na sandar turawaana nunawa a kasa:

Siffar tsari da sigogi na sandar sake saitiana nunawa a kasa:

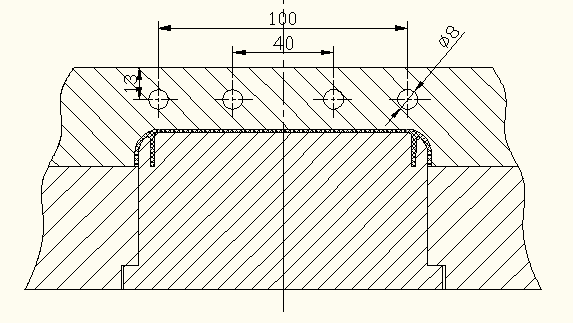

2.9 Zane na tsarin sanyaya

Kamar yadda sanyaya ba daidai ba ne, tsarin sanyaya na tashar sanyaya ya kamata ya kasance kamar yadda zai yiwu, wannan zabin zane don 4. Nisan tashar tashar daga sararin samaniya yana daidai, kuma sprue kuma yana ƙarfafa don sanyaya.Tsarin sanyaya yana ɗaukar nau'in rarrabawar DC, wanda ke da tsari mai sauƙi da aiki mai dacewa.

Tsarin tsarin sanyaya kamar haka:

Sashi na uku:Duba lissafin allura mold

3.1.Duba sigogin tsari masu alaƙa na injin allura

3.1.1 Duba matsakaicin ƙarar allurar

3.1.2 Duba ƙarfin matsawa

3.1.3 Duba tafiyar buɗewar mold

3.2.Duba kaurin bangon gefe da farantin ƙasa na rami rectangular

3.2.1 Bincika kaurin bangon gefen rami na rectangular

3.2.2 Bincika kaurin ramin ƙasan farantin rectangular

ƙarshe

Freshness Keeper tawagar ta zanen Xie Master wannan zane ne yafi ga mold zane na filastik abincin abincin akwatin murfin, ta hanyar bincike na kayan filastik murfin akwatin abincin rana, tsarin sassa filastik da fasaha, sa'an nan kuma m, kimiyya kammala allura mold. zane.

Freshness Keeper Fa'idodin ƙirar shine don sauƙaƙe injin ƙirar allura gwargwadon yuwuwar don tabbatar da ingancin sassan filastik, gajarta zagayowar gyare-gyare, ƙananan farashin samarwa.Mahimman abubuwan da aka tsara na zane sune tsari na gyare-gyaren allura, shimfidar rami, zaɓin yanki, tsarin gating, tsarin fitarwa, tsarin lalata, tsarin sanyaya, zaɓin injin ƙirar allura da bincika sigogi masu dacewa da ƙirar manyan sassa.

Freshness Keeper ta musamman zane ya ta'allaka ne a cikin zane na zub da tsarin, zuba tsarin kofa hannun riga da sakawa zobe ga guda part, tabbatar da rayuwar mold, da kuma kayan zažužžukan, aiki, zafi magani da kuma maye gurbin su dace;Ƙofar ita ce nau'in ƙofar kai tsaye, wanda ke buƙatar shimfidawa biyu, kuma ana amfani da tsayayyen zane mai nisa don iyakance rabuwar farko.Tsarin yana da sauƙi kuma mai dacewa.

Lokacin aikawa: Nov-01-2022